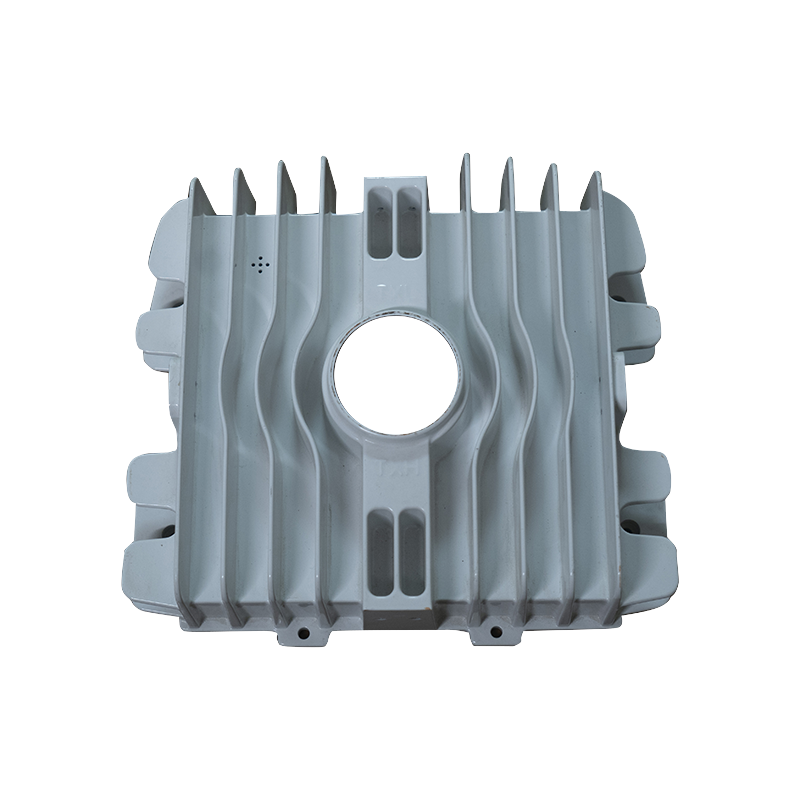

Kwindawo yoomatshini boshishino kunye nobunjineli beemoto, ukubaluleka kwamacandelo ahlala ixesha elide aqinisekisa ukusebenza kakuhle akukwazi ukugqithiswa.Phakathi kwala macandelo,i-aluminium alloy casting coversziye zavela njengesisombululo esibalulekileyo nesiguquguqukayo.Ngamandla awo akhethekileyo, ubume obukhaphukhaphu, kunye neempawu ezimelana nomhlwa, ezi zigqubuthelo zidlala indima ebalulekileyo ekukhuseleni oomatshini ababalulekileyo kunye nokuphucula ukusebenza kwabo kukonke.Esi sithuba sebhlog sijonga ukubaluleka kwezigqubuthelo zokuphosa ialluminiyam, sikhanyisela kwiimpawu zabo ezibalulekileyo, izibonelelo, kunye nokusetyenziswa.

1. Ukhuseleko Olomeleleyo:

Izigqubuthelo zokuphosa ialluminiyam ziyilelwe ngokukodwa ukukhusela kunye nokukhusela izinto ezibalulekileyo kwizinto ezahlukeneyo zangaphandle, kubandakanya uthuli, inkunkuma, ukufuma, kunye neemeko zemozulu ezimandundu.Ngokusebenza njengesithintelo esikhuselayo, ezi zigqubuthelo zithintela izinto ezingafunekiyo ukuba zingangeni kwaye ezinokuba nokonakalisa oomatshini, zinciphisa umngcipheko wokungasebenzi kakuhle okanye ukophuka.Ukomelela kwabo kunye nokuchasana kwempembelelo kuqinisekisa ngakumbi ubomi obude bamacandelo agqunyiweyo.

2. Ikhaphukhaphu kwaye Iguquguquka:

Xa kuthelekiswa nezinye izinto ezifana nentsimbi okanye intsimbi, iialloyi zealuminiyam zibonisa iimpawu ezikhaphukhaphu ezimangalisayo, zizenza zilungele ukuphosa izigqubuthelo.Ubunzima obuncitshisiweyo bunenzuzo ngokubhekiselele kuthutho, ukuphatha, kunye nokulula kokufakela.Ubume obukhaphukhaphu buvumela ukwanda kokuguquguquka ngelixa kuyilwa amacandelo anzima, iqinisekisa ukufaneleka ngokugqibeleleyo kunye nokusebenza okuphuculweyo.Ngaphaya koko, iialloyi ze-aluminiyam zinokuphoswa kwiimilo ezahlukeneyo, zivumela ukwenziwa ngokwezifiso koqweqwe lokuphosa kwiimfuno zezixhobo ezithile.

3. I-Thermal Conductivity:

Olunye uphawu oluluncedo lwe-aluminium alloy casting covers yi-thermal conductivity egqwesileyo.Iialloyi ze-aluminiyam zinamandla okuphelisa ubushushu obuphezulu, obunceda ekulawuleni ngokufanelekileyo ubushushu obuveliswa ngoomatshini abavalelweyo.Lo mgangatho ubaluleke kakhulu kwizicelo apho ukulawulwa kweqondo lokushisa kubalulekile ukugcina ukusebenza kakuhle okanye ukuthintela ukushisa.Ngokukhupha ubushushu ngokufanelekileyo, izigqubuthelo zokuphosa ialluminiyam zinceda ukwandisa ubomi besixhobo esibuthathaka kunye nokuphucula ukusebenza kwazo zonke.

4. UKuxhathisa uKutya:

Ukongeza ekomeleleni kwazo, iialloyi ze-aluminiyam ziyaziwa ngokuxhathisa kwazo ngokugqwesileyo kwi-corrosion.Le propati ibenza bafaneleke ngokukodwa ukuphosa izigqubuthelo ezivezwe kwizinto ezahlukeneyo zokusingqongileyo, ezifana nokufuma, iikhemikhali, okanye amanzi etyuwa.Ukuxhathisa umhlwa akuqinisekisi kuphela ukukhuselwa koomatshini kodwa kunciphisa iindleko zokugcina ezinxulumene nokulungiswa okanye ukutshintshwa ngenxa yomonakalo womhlwa.

5. Uluhlu olubanzi lwezicelo:

I-Aluminiyam i-alloy casting coversFumana usetyenziso olubanzi kumashishini ahlukeneyo.Ngokuqhelekileyo zisetyenziselwa ukuveliswa kweemoto kwii-injini zokugquma, iibhokisi zegiya, kunye nezixhobo zokuhambisa.Kumzi mveliso we-aerospace, zisebenza njengezindlu ezikhuselayo kwizinto ezibalulekileyo ze-elektroniki okanye iinkqubo ze-hydraulic.Ukongeza, baqeshwe ngokubanzi kwimveliso yoomatshini abanzima, izixhobo zokuvelisa amandla, kunye nabathengi be-elektroniki, ngenxa yendalo yabo eguquguqukayo kunye neenzuzo abazinikezelayo.

Izigqubuthelo zokwenziwa kwealluminiyam ziye zaba yinxalenye yoomatshini bale mihla ngenxa yeempawu zabo ezingenakuthelekiswa nanto zokuqina, uyilo olukhaphukhaphu, ukuhanjiswa kwe-thermal, kunye nokuxhathisa umhlwa.Ezi zigqubuthelo azikhuseli kuphela amacandelo abalulekileyo kodwa zikwaphucula ukusebenza kunye nokuqinisekisa ixesha elide lezixhobo zokusebenza.Njengoko itekhnoloji ihambela phambili, imfuno ye-aluminium alloy casting covers kulindeleke ukuba ikhule, ibonelela kumashishini ahlukeneyo axhomekeke koomatshini abaqinileyo nabasebenzayo.

Ixesha lokuposa: Nov-20-2023