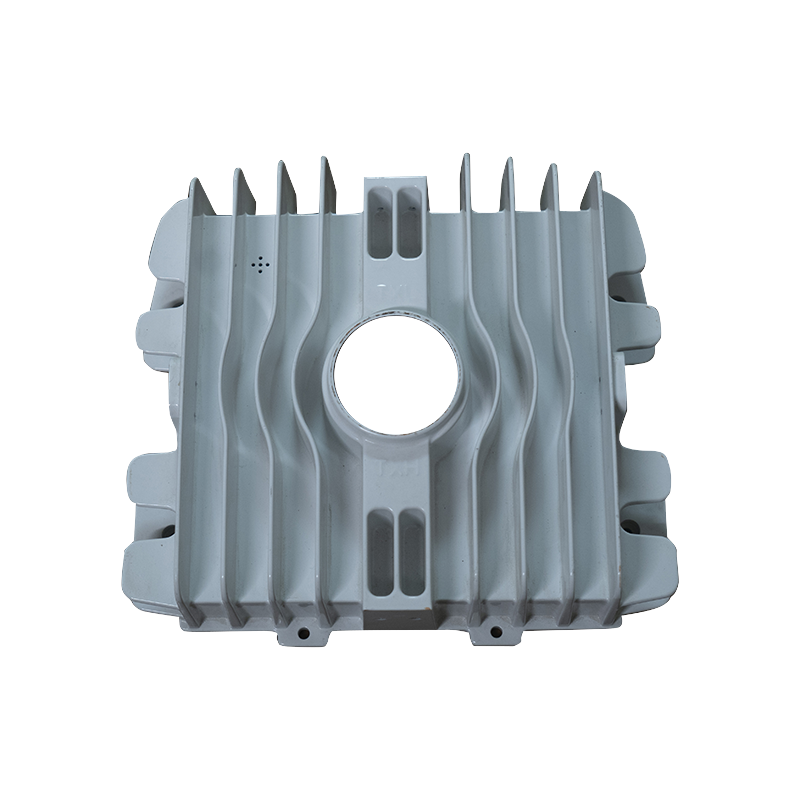

Kwicandelo loomatshini bemizi-mveliso kunye nobunjineli beemoto, ukubaluleka kwezinto ezihlala ixesha elide eziqinisekisa ukusebenza kakuhle akunakugxininiswa kakhulu. Phakathi kwezi zinto,izigqubuthelo zokuphosa i-aluminium alloyziye zavela njengesisombululo esibalulekileyo nesinokuguquguquka. Ngenxa yamandla azo angaqhelekanga, ubume bazo obulula, kunye neempawu ezimelana nokugqwala, ezi zigqubuthelo zidlala indima ebalulekileyo ekukhuseleni oomatshini ababalulekileyo nasekuphuculeni ukusebenza kwazo ngokubanzi. Le posi yebhlog igxila kukubaluleka kwezigqubuthelo zokuphosa i-aluminium alloy, ikhanyisa iimpawu zazo ezibalulekileyo, iingenelo kunye nokusetyenziswa kwazo.

1. Ukhuseleko Oluqinileyo:

Izigqubuthelo zokubumba i-aluminium zenzelwe ngokukodwa ukukhusela nokukhusela izinto ezibalulekileyo kwizinto ezahlukeneyo zangaphandle, kubandakanya uthuli, ubumdaka, ukufuma, kunye neemeko zemozulu ezinzima. Ngokusebenza njengomqobo wokukhusela, ezi zigqubuthelo zithintela izinto ezingafunekiyo ukuba zingangeni kwaye zingonakalise oomatshini, zinciphisa umngcipheko wokungasebenzi kakuhle okanye ukonakala. Ukuqina kwazo kunye nokumelana kwazo nempembelelo kuqinisekisa ngakumbi ukuba iindawo ezigqunyiweyo zihlala ixesha elide.

2. Ilula kwaye isebenziseka ngeendlela ezininzi:

Xa kuthelekiswa nezinye izinto ezifana nentsimbi okanye isinyithi, ii-alloys ze-aluminium zibonisa iimpawu ezikhaphukhaphu ezimangalisayo, nto leyo ezenza ukuba zilungele ukugquma. Ubunzima obuncitshisiweyo buluncedo ngokubhekiselele ekuthuthweni, ekuphathweni, nasekufakelweni lula ngokubanzi. Olu hlobo lukhaphukhaphu lwenza kube lula ngakumbi ukuguquguquka ngelixa kuyilwa izinto ezintsonkothileyo, kuqinisekisa ukulingana ngokugqibeleleyo kunye nokusebenza okuphuculweyo. Ngaphezu koko, ii-alloys ze-aluminium zinokugquma kwiimo ezahlukeneyo, okuvumela ukwenziwa ngokwezifiso kwezigqubuthelo zokugquma ngokweemfuno zezixhobo ezithile.

3. Ukuqhuba Ubushushu:

Olunye uphawu oluluncedo lwezigqubuthelo zokuphosa i-aluminium alloy kukuba ziqhuba kakuhle kakhulu ubushushu. Ii-aluminium alloys zinamandla aphezulu okusasaza ubushushu, nto leyo enceda ekulawuleni ngempumelelo ubushushu obuveliswa ngoomatshini abavalekileyo. Olu mgangatho lubaluleke kakhulu kwizicelo apho ukulawulwa kobushushu kubalulekile ukugcina ukusebenza kakuhle okanye ukuthintela ubushushu obugqithisileyo. Ngokususa ubushushu ngokufanelekileyo, izigqubuthelo zokuphosa i-aluminium alloy zinceda ukwandisa ubomi bezixhobo ezinobuthathaka kwaye zonyuse ukusebenza kwazo ngokubanzi.

4. Ukumelana nokugqwala:

Ukongeza ekuqineni kwazo, ii-alloys ze-aluminium zaziwa ngokumelana kwazo okugqwesileyo nokugqwala. Olu phawu luzenza zifaneleke ngakumbi kwiingubo zokubumba ezivezwa kwizinto ezahlukeneyo zokusingqongileyo, ezinje ngomswakama, iikhemikhali, okanye amanzi anetyuwa. Ukumelana nokugqwala akuqinisekisi nje kuphela ukukhuselwa koomatshini kodwa kunciphisa iindleko zokulungisa ezinxulumene nokulungiswa okanye ukutshintshwa ngenxa yomonakalo wokugqwala.

5. Uluhlu olubanzi lwezicelo:

Izigqubuthelo zokuphosa i-aluminium alloyZifumana usetyenziso olubanzi kumashishini ahlukeneyo. Zisetyenziswa kakhulu kwimveliso yeemoto kwizigqubuthelo zeenjini, iibhokisi zegiya, kunye nezigqubuthelo zothumelo. Kwishishini leenqwelo-moya, zisebenza njengeendawo zokukhusela izinto ezibalulekileyo ze-elektroniki okanye iinkqubo ze-hydraulic. Ukongeza, zisetyenziswa kakhulu kwimveliso yoomatshini abanzima, izixhobo zokuvelisa umbane, kwanakwii-elektroniki zabathengi, ngenxa yendalo yazo eguquguqukayo kunye neenzuzo ezibonelela ngazo.

Izigqubuthelo zokuphosa i-aluminium alloy ziye zaba yinxalenye ebalulekileyo yoomatshini banamhlanje ngenxa yeempawu zabo ezingenakuthelekiswa nanto zokuqina, uyilo olukhaphukhaphu, ukuqhuba kobushushu, kunye nokumelana nokugqwala. Ezi zigqubuthelo azikhuseli nje kuphela izinto ezibalulekileyo kodwa zikwaphucula ukusebenza kwaye ziqinisekisa ubomi bezixhobo obude. Njengoko ubuchwepheshe buqhubeka, kulindeleke ukuba imfuno yezigqubuthelo zokuphosa i-aluminium alloy ikhule, ilungele amashishini ahlukeneyo axhomekeke koomatshini abaqinileyo nabasebenzayo.

Ixesha lokuthumela: Novemba-20-2023