Kwihlabathi leenxalenye zeemoto, ukuchaneka kunye nomgangatho zibaluleke kakhulu. Ukususela kuyilo lokuqala ukuya kwimveliso yokugqibela, icandelo ngalinye lidlula kwinkqubo yokwenziwa ngononophelo ukuqinisekisa ukusebenza kakuhle. Enye into ebalulekileyo yindlu yeebhokisi zegiya ze-aluminium. Kule bhlog, siza kujonga kwihlabathi elintsonkothileyo lokwenziwa kwe-mold, ukubaluleka kweeprototypes, kunye nemigangatho yomgangatho engqongqo eyenza izindlu zeebhokisi zegiya ze-aluminium zibe ngcono kwishishini leemoto.

Ubugcisa bokubumba iMold

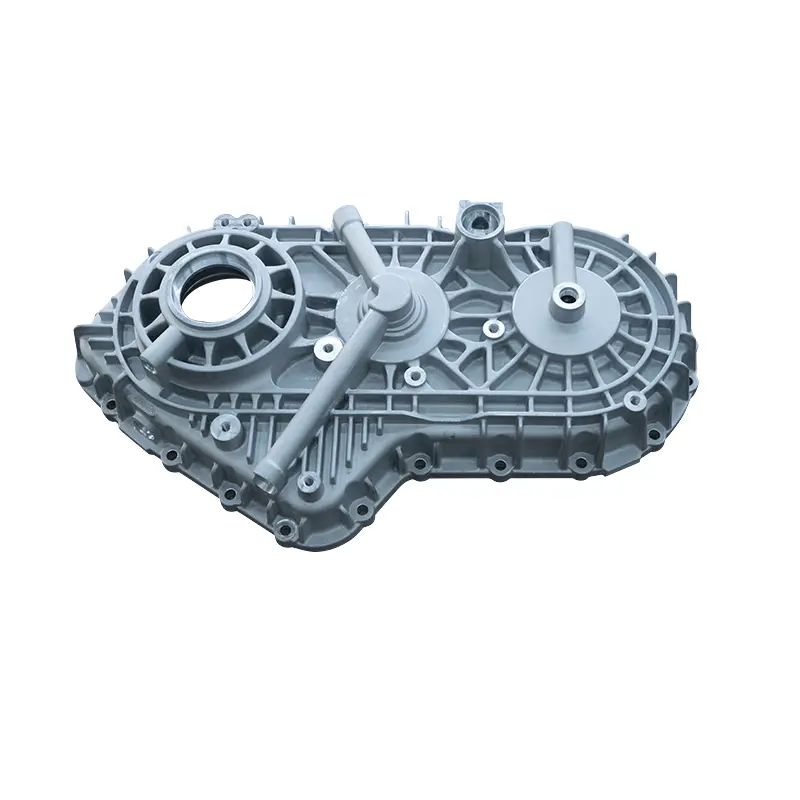

Umatshini wokwenza isikhunta udlala indima ebalulekileyo ekudaleni izindlu zebhokisi yegiya ye-aluminium. Ngoncedo lwezixhobo zamva nje, iisikhunta zenziwa ngononophelo ngendlela esondeleyo. Oku kuchanekileyo kuvumela ukudalwa kweenkqubo zegiya ezingenasiphako, kuqinisekisa ukusebenza okungenamthungo ngaphakathi kothumelo lweemoto. Le nkqubo ibandakanya ukusebenzisa iindlela eziphambili ezifana nomatshini wokwenza i-computer numerical control (CNC) ukuze kufezekiswe iimilo kunye nobukhulu obufunekayo. Iingcali zobugcisa ezineliso elibukhali lokufumana iinkcukacha zisebenzisa izakhono zazo ukwenza iisikhunta eziza kuvelisa izindlu zebhokisi yegiya kamva. Ukugqitywa komphezulu ococekileyo, uyilo oluntsonkothileyo, kunye nokulinganisa okuchanekileyo konke kufezekiswa ngobugcisa bomatshini wokwenza isikhunta.

Inzuzo yoMzekelo

Abathengi badla ngokufuna iprototype yendlu yegiya ye-aluminium ukuqinisekisa ukuba iyahlangabezana nolindelo lwabo. Eli nyathelo linceda ekuchongeni naziphi na iziphene zoyilo, ukwenza uphuculo olufunekayo, kunye nokulungelelanisa imveliso ngokweemfuno zomthengi. Iiprototypes zikwavumela iinjineli ukuba zihlalutye ukuhambelana kwendlu nenkqubo yeemoto iyonke kwaye zihlole ukuqina kwayo. Ngokwenza iprototype, abavelisi banokulungisa uyilo kwaye benze naluphi na uhlengahlengiso olufunekayo ngaphambi kokuba kwenziwe imveliso epheleleyo. Oku kuqinisekisa ukusebenza kakuhle kweendleko kunye nokwaneliseka kwabathengi, ngelixa kunciphisa umngcipheko weziphene okanye ukubuyiselwa kwempahla.

Ukuzibophelela kuMgangatho

Umgangatho sisiseko senkqubo yokwenziwa kwezindlu zegiya ze-aluminium. Ukususela ekukhethweni kwezinto ukuya ekuhlanganisweni kokugqibela, abavelisi balandela amanyathelo okulawula umgangatho angqongqo. Inqanaba ngalinye lijongwa kwaye livavanywa ukuqinisekisa ukuba imveliso egqityiweyo iyahlangabezana okanye idlula imigangatho yoshishino. Izixhobo zokuhlola umgangatho ophezulu zisetyenziselwa ukufumanisa naluphi na uphambuko kwiinkcukacha, okuqinisekisa ukuba indlu nganye yegiya yegiya ayinasiphako ekusebenzeni nasekubonakaleni. Abavelisi bakwaqhuba uvavanyo oluqinileyo lokusebenza, belinganisa iimeko zehlabathi lokwenyani ngaphambi kokuba nayiphi na imveliso iziswe kwimarike. Oku kuzibophelela kumgangatho kuqinisekisa ukuthembeka kunye nobude bendlu yegiya ye-aluminium, kwanelisa abavelisi kunye nabasebenzisi bokugqibela ngokufanayo.

Ishishini leemoto lixhomekeke ekuchanekeni, ekusebenzeni, nasekugqweseni. Ukuveliswa kwezindlu zeegiya ze-aluminium kubonisa olu kuzinikela ekugqibeleleni. Ngokusebenzisa umatshini wokubumba ocokisekileyo, ukudalwa kweeprototypes, kunye nokuzibophelela okungagungqiyo kumgangatho, abavelisi baqinisekisa ukuba indlu nganye yeegiya zeemoto iyamelana neemfuno zehlabathi leemoto. Ngokuqhubela phambili kwiindlela zokwenza imveliso kunye nemigangatho yeshishini ehlala itshintsha,izindlu zebhokisi yegiya ye-aluminium qhubeka nokuba phambili ekuphuculeni iimoto, ukubonelela ngokuqina, ukuthembeka, kunye nokusebenza okungenamthungo.

Ixesha lokuthumela: Agasti-03-2023