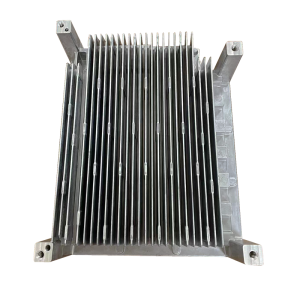

Indlu ye-heatsink ye-aluminium ephosa i-die casting yemveliso ye-broadband engenazingcingo

Uphawu lokuphosa i-Die:

I-die casting yinkqubo yokuvelisa esebenza kakuhle kakhulu enokuvelisa iindawo ezineemilo ezintsonkothileyo. Ngokusebenzisa i-die casting, ii-heatsink fins zinokufakwa kwisakhelo, indlu okanye indawo ebiyelweyo, ukuze ubushushu budluliselwe ngqo ukusuka kumthombo ukuya kwindawo engqongileyo ngaphandle kokumelana okongezelelweyo. Xa busetyenziswa ngokupheleleyo, i-die casting ayiboneleli kuphela ngokusebenza kakuhle kobushushu, kodwa ikwabonelela ngokonga okukhulu kwixabiso.

Inzuzo ye-Die Casting Aluminium Heatsink

Iingenelo okanye iingxaki ze-heatsink edie-cast kuxhomekeke kuhlobo lwezinto ezenziwe ngazo. Umzekelo, i-aluminium yeyona nto isetyenziswa kakhulu ukuvelisa ii-heatsink ezidie-cast. Ezinye zezibonelelo eziphambili ze-heatsinks ezidie-cast zidweliswe ngezantsi:

1. Okokuqala, kufuneka uqaphele ukuba ii-heatsinks ezifakwe kwi-die-cast zisebenza kakuhle kwizixhobo zombane.

2. Ii-heatsinks ezifakwe kwi-die cast zibandakanya inkqubo yokuphosa, ngoko ke, zinokubakho kwiindidi ezinkulu.

3. Iifins ze-heatsinks ezifakwe kwi-die-cast zinokubakho kwiindawo ezahlukeneyo, iimilo, kunye nobukhulu.

4. Kukho ubunzima obunciphileyo kwiindlela zoyilo lwe-heatsink ezidityanisiweyo. Ngenxa yoko, kukho isidingo esincinci sokwenza i-machining.

5.Ungongeza iindlela ezahlukeneyo zokukhupha ubushushu kwisinki yobushushu ediyelwe nge-die-cast.

6. Iiheatsinks ezifakwe kwi-die cast zixabiso eliphantsi kwaye zingathengiswa ngobuninzi.

7. Ungaba neendlela ezahlukeneyo zokujonga imveliso kwii-heatsinks ezidiyelweyo. Nokuba zinjani na iindawo ezijongwayo, ukuhamba kobushushu kugcinwa ngokufanelekileyo.

8. Abavelisi banokwenza ngokwezifiso ii-heatsinks ezifakwe kwi-die-cast ngokweemfuno zakho.

9. Singavelisa iintlobo ezahlukeneyo zesigqubuthelo se-heatsink, izindlu, isiseko sonxibelelwano, izixhobo ze-elektroniki.

Isiqulatho

Uyilo lwe-Aluminium Casting Iindlela ezilungileyo: Uyilo lweMveliso (DFM)

Izinto ezili-9 ekufuneka uziqwalasele xa uYila i-Aluminium Die Casting:

1. Umgca wokwahlulahlula 2. Izikhonkwane zokukhupha umoya 3. Ukushwabana 4. Umzobo 5. Ubukhulu bodonga

6. Iifillets kunye neeradii7. Abaphathi 8. Iimbambo 9. Izicucu ezingaphantsi 10. Imingxunya kunye neefestile