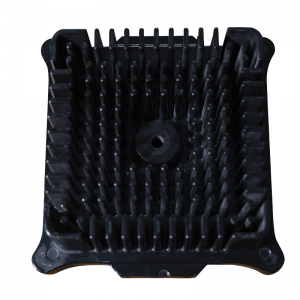

I-heatsink yesiko eyenziwe ngokwezifiso yeRadiator

Inkqubo yesinki yobushushu

Uyilo lwezixhobo

Ukuphoswa kwe-die yoxinzelelo oluphezulu

Ukusika

Ukususa iimbumbulu

Ukuqhumisa isanti

Ukupolisha umphezulu

Ukwaleka komgubo

Ukuthepha kunye nokulungisa i-CNC

Isixhobo esijikelezileyo

Unyango Lomphezulu

1. I-oxidation yeekhemikhali

2. Ukupeyinta

3. I-Electrophoresis

4. Ukufaka i-anodizing

5. Ukwaleka ngomgubo

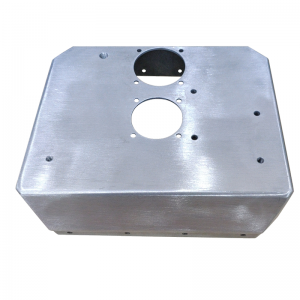

Izinki zobushushu ezifakwe nge-die cast

Izinki zobushushu ezifakwe kwi-die cast zifanelekile ukuba ufuna isinki yobushushu ye-aluminium eyenzelwe wena. Zenziwa ngokunyanzela i-aluminium engamanzi phantsi koxinzelelo oluphezulu kwiimold zentsimbi. Isinki yobushushu efakwe kwi-die casting ithandwa kakhulu kwimarike kuba yenziwe nge-aluminium alloy. Le yeyona nto ikhethwayo kwisinki yobushushu efakwe kwi-die casting. Ezi nkqubo ze-die casting zifanelekile ukuhlangabezana neemfuno zeprojekthi kwaye zenze imveliso ekhawulezileyo.

Ixesha lokukhokela elikhawulezayo lithatha iintsuku ezingama-35-40 kuphela

Ukusebenza okuphezulu kwiimpahla zomphezulu ezigqityiweyo

Ubukhulu obuqinileyo obuphezulu bulawulwa ngaphakathi kwe-+/- 0.05mm

Iinjineli zinceda ekugqityweni ukusuka kuyilo ukuya ekuvelisweni

Iingenelo zeeDie Cast Heat Sinks

Xa kuthelekiswa nezinye iindlela zokuvelisa, i-die casting inikezela ngezi zibonelelo zilandelayo:

1. Velisa iimilo ze-3D ezintsonkothileyo ezingenakwenzeka xa kukhutshelwa ngaphandle okanye kusenziwa izinto zokubumba

isinki yobushushu ye-aluminium, isakhelo, indlu, indawo ebiyelweyo kunye nezinto zokubopha zinokudityaniswa kwi-casting enye

2.Iimbobo zingafakwa kwi-die casting

3.Izinga eliphezulu lemveliso kunye neendleko eziphantsi

4. Ukunyamezelana okuqinileyo

5. Uzinzo ngokwemilinganiselo

6. Akufuneki ukuba kwenziwe umatshini wesibini

Zibonelele ngendawo ethe tyaba kakhulu (elungele ukudibana phakathi kwesinki yobushushu kunye nomthombo)

Amanqanaba okumelana nokugqwala ukusuka kokuhle ukuya kophezulu

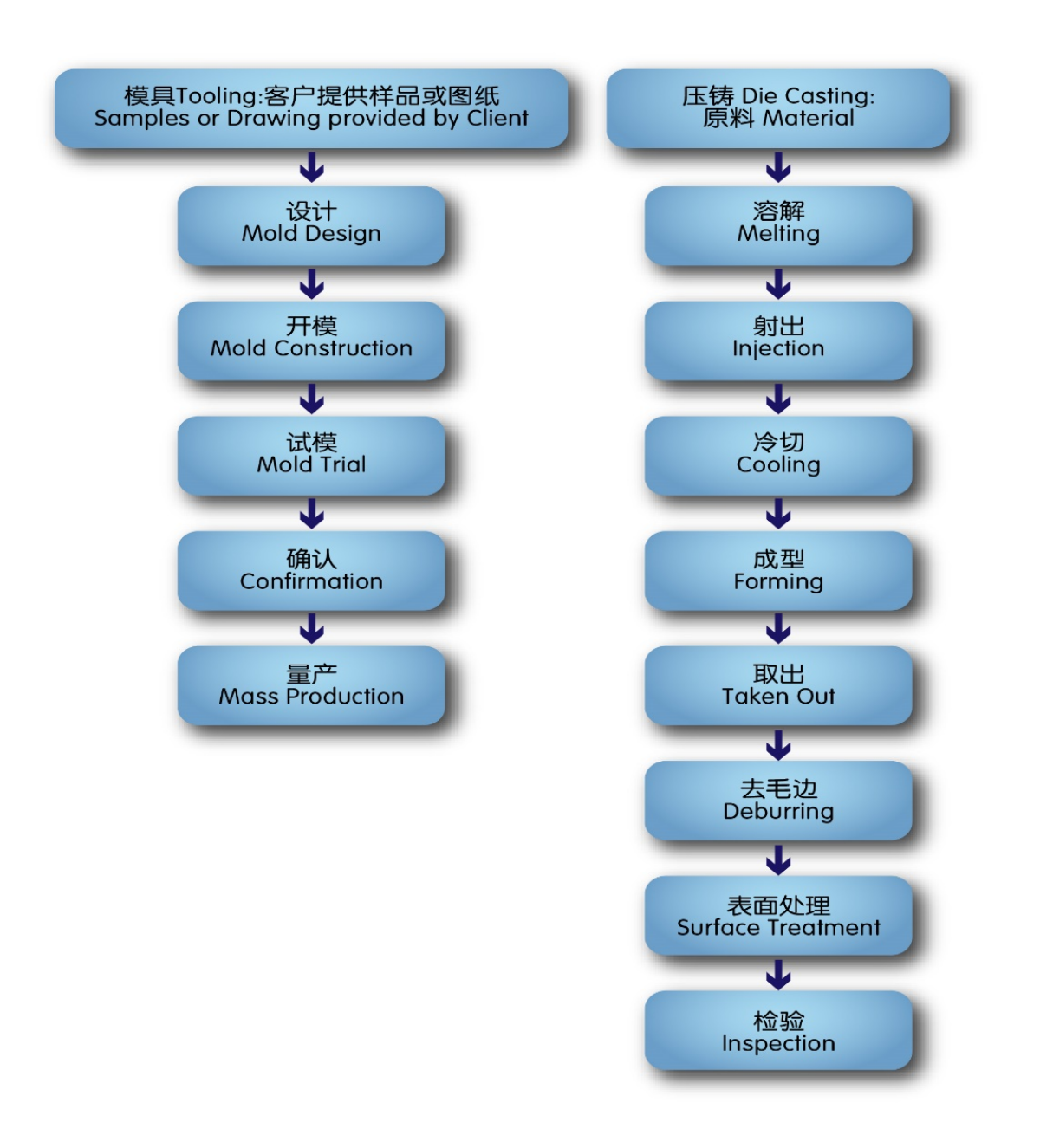

Ukuhamba kwenkqubo yeKingrun

Xa kuthelekiswa nezinye iindlela zokuvelisa, i-die casting inikezela ngezi zibonelelo zilandelayo:

1. Velisa iimilo ze-3D ezintsonkothileyo ezingenakwenzeka xa kukhutshelwa ngaphandle okanye kusenziwa izinto zokubumba

Isinki yobushushu, isakhelo, indlu, indawo ebiyelweyo kunye nezinto zokubopha zinokudityaniswa kwi-casting enye

2.Iimbobo zingafakwa kwi-die casting

3.Izinga eliphezulu lemveliso kunye neendleko eziphantsi

4. Ukunyamezelana okuqinileyo

5. Uzinzo ngokwemilinganiselo

6. Akufuneki ukuba kwenziwe umatshini wesibini

Zibonelele ngendawo ethe tyaba kakhulu (elungele ukudibana phakathi kwesinki yobushushu kunye nomthombo)

Amanqanaba okumelana nokugqwala ukusuka kokuhle ukuya kophezulu

Ukukhusela i-EMI kunye ne-RFI ngendlela egqwesileyo