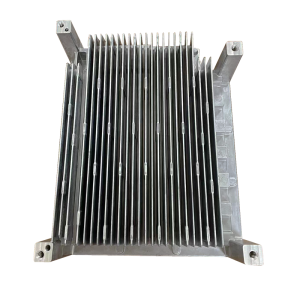

I-heatsink ye-aluminium die cast enamaphiko akhutshiweyo

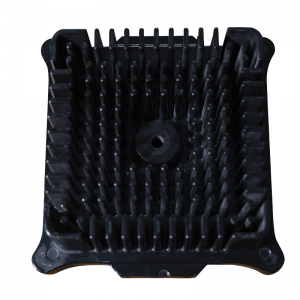

Ukuphoswa kwedayi yinkqubo yokuvelisa esebenza kakuhle kakhulu enokuvelisa iindawo ezineemilo ezintsonkothileyo. Ngokuphoswa kwedayi, amaphiko esinki yobushushu anokufakwa kwisakhelo, indlu okanye indawo ebiyelweyo, ukuze ubushushu budluliselwe ngqo ukusuka kumthombo ukuya kwindawo engqongileyo ngaphandle kokumelana okongezelelweyo. Xa busetyenziswa ngokupheleleyo, ukuphoswa kwedayi akuboneleli kuphela ngokusebenza kakuhle kobushushu, kodwa kukwabonelela ngokonga okukhulu kwixabiso.

Inzuzo ye-die Cast Heatsink

Ifanelekile kwiimveliso ezahlukeneyo ezimile okweemilo.

Nciphisa iindleko zokucubungula.

Uhlalutyo lobuchwephesha lokuhamba komngundo ukuze kufinyezwe ixesha lomjikelo wophuhliso lwemveliso kwaye kuphuculwe izinga lokuvelisa imveliso.

Umatshini we-CMM ozenzekelayo ngokupheleleyo ukuqinisekisa ukuba ubukhulu bemveliso buyahambelana nemimiselo.

Izixhobo zokuskena ze-X-ray ziqinisekisa ukuba akukho ziphene ngaphakathi kwimveliso efakwe kwi-die-cast.

Ukwambathisa ngomgubo kunye neCataphoresis kuqinisekisa umgangatho ozinzileyo wonyango lomphezulu wemveliso.

Inkqubo ephambili yokukhupha amaphiko enziwe nge-extrusion + i-Die casting

Amaphiko akhutshiweyo ngezixhobo zokukhupha.

Umzimba we-aluminium ophoswe nge-die.

Umatshini wokusika ngesarha/ukusika nge-CNC ngokwemilo efunekayo.

Umbhobho wobushushu wokuhlanganisa/ityhubhu yobhedu/ityhubhu yentsimbi engatyiwayo/ispring/isikrufu ukuze ufumane i-heatsink egqityiweyo.